Description

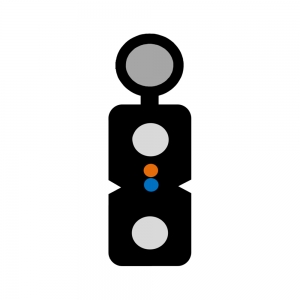

COLOUR CODING:

Colour of Fibres in a Tube : BLUE, ORANGE, GREEN, BROWN / NATURAL

Colour of Loose Tubes: BLUE, ORANGE, GREEN, BROWN, SLATE, WHITE

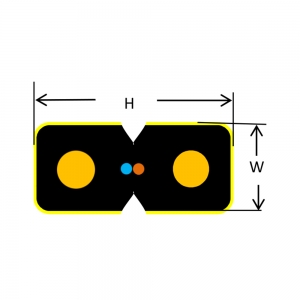

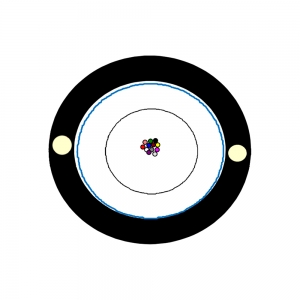

CABLE CONSTRUCTIONAL DETAILS:

- Primary Coated Fibre: Single Mode – G 652

- Tube Filling Compound: Thixotropic Jelly

- Loose Tube(s): PBTP

- Central Strength Member: FRP Rod

- Water Blocking: Water Swellable Yarns over FRP

- Core Wrapping over S-Z core: Water Blocking Tape

- Rip cords: 1 Nos (under HDPE sheath)

- Outer Sheath ( T= 1.5 mm Nominal): UV protected Black HDPE

DELIVERY INFORMATION:

- Nominal Cable Weight (Kg/Km): 65 ± 10

- Nominal Cable Diameter (mm): 9.0 ± 0.5

- Standard Length per Drum (Mtr): 4000 ± 10 %

CABLE SHEATH MARKING:

Cable sheath shall be marked in white colour with Hot Foil Indentation method. Marking details can be customized. Below mentioned details are generally marked on the cable sheath.

Characteristics

MECHANICAL CHARACTERISTICS:

| Temperature Range (IEC 60794-1-2-F1) |

Laying and Installation -20° to +70°C |

Operation -30° to +70°C |

Transport and Storage -40° to +70°C |

| Cable Bending Radius (IEC 60794-1-2-E11A) |

Long Term 20 x D, D = Cable Diameter |

Short term 10 x D, D = Cable Diameter |

|

| Repeated Bending (IEC 60794-1-2-E6) |

30 Cycle, r= 20 X D, 10 Kg Load, D = Cable Diameter |

|

|

| Tensile Force (IEC 60794-1-2-E1) |

Short Term 1500N |

Long Term 750N |

|

| Torsion Resistance (IEC 60794-1-2-E7) |

10 Cycle (± 180°) 10 Kg Weight, L= 2 Mtr |

|

|

| Crush Resistance (IEC 60794-1-2-E3) |

2000 N (100 X 100 mm) for 60 sec |

|

|

| Impact Resistance (IEC 60794-1-2-E4) |

25Nm load, 3 Nos |

|

|

| Kink Resistance (IEC 60794-1-2-E10) |

10 x D, D = Cable Diameter |

|

|

| Water Penetration (IEC 60794-1-2-F5B) |

1 Mtr Water Head, 3 Meter Cable Sample, 24 Hours |

|

|

* Change in Attenuation after the test shall be less than 0.05dB

OPTICAL CHARACTERISTICS:

Fibre used in the cable manufacturing fully comply to ITU-T-Rec G 652.

- at 1310 nm < 0.38 dB/Km

- at 1550 nm < 0.25 dB/Km